This is the fourth article in a 5-part series about automotive technologies. This installment will discuss the development of the in-vehicle network (IVN) in the context of evolving automotive electrical/electronic (E/E) architecture and the opportunities of PCIe repeater integrated circuits (ICs).

When discussing the emergence of autonomous driving technology and the intelligent cockpit, we cannot overlook the evolution of automotive E/E architecture. In the previous article, we explained that the shift towards centralized architecture has driven the evolution of data storage technology – from traditional eMMC and UFS flash memory to more powerful Peripheral Component Interconnect Express (PCIe) 3.0 and PCIe 4.0 SSDs. Similarly, in-vehicle networks have also undergone an evolution. In addition to well-known standards such as CAN (controller area network), LIN (local interconnect network), MOST (media-oriented systems transport), FlexRay and Ethernet, given the leading position of Phison in PCIe technology, Phison is also paying attention to the potential opportunities of the PCIe interface.

Beyond its extensive ecosystem support, PCIe offers exceptionally low latency, outstanding scalability, high bandwidth and reliability. These advantages position PCIe as a potential key player in automotive in-vehicle network systems. Phison believes that PCIe holds significant potential in the future of the automotive industry.

The history of traditional in-vehicle protocols

The evolution of IVN protocols has played a crucial role in the evolution of automobiles. The IVNs connect various microcontrollers, electronic control units (ECUs), sensors and actuators within the vehicle, enabling them to communicate and collaborate, thus enhancing functionality and improving the driving experience.

Important IVN protocols include:

CAN(controller area network)

CAN was invented in the early 1980s, marking the beginning of automotive data transmission protocols. As a serial bus protocol, CAN allowed ECUs and subsystems in vehicles to communicate with each other. CAN is known for its reliability and robust fault tolerance, and it continues to be widely used today. However, automakers found that implementing CAN for every part in a vehicle could be cost-prohibitive, despite its strong capabilities and reliability.

LIN(local interconnect network)

In 2002, the LIN Consortium introduced a lower-cost serial communication protocol. LIN serves as an alternative to CAN in certain scenarios and is typically used for subsystems in vehicles where performance, data bandwidth and security are less critical. These subsystems include functions like windshield wipers, windows, HVAC, seat motors, door locks, etc.

MOST(media-oriented systems transport)

In 1998, in response to the increasing demand for multimedia and entertainment, the MOST protocol was introduced. It offered a high-speed solution for transmitting high-quality audio and video data using optical fibers. The MOST150, released in 2007, achieved speeds of up to 150 Mbps. However, as automotive entertainment systems began to require higher bandwidth, MOST gradually gave way to automotive Ethernet and its significance declined over time.

FlexRay

In 2006, BMW became the pioneer in adopting FlexRay as the communication protocol for its new fast adaptive damping system. FlexRay supports data rates up to 10 Mbps, faster than CAN FD’s 5 Mbps, and it offered higher fault tolerance through redundant designs and improved real-time capabilities. As a result, it was well-suited for high-performance powertrain systems and safety applications. However, its higher cost and complexity limited its popularity and only German automakers used it in production vehicles. FlexRay is also gradually being replaced by Ethernet in applications where high-speed requirements and cost sensitivity are paramount.

Ethernet

As early as 2008, BMW took the lead in adopting Ethernet as the interface for external diagnostics and software updates. However, it wasn’t until 2016 that traditional IVN protocols gradually proved inadequate for high-speed data transmission scenarios. In response to this need, IEEE introduced automotive Ethernet standards, including IEEE 802.3bw (100Base-T1) and 802.3bp (1000Base-T1), with speeds of 100 Mbps and 1000 Mbps, respectively. These standards were adapted for automotive environments, addressing factors such as cabling, encoding, weight and length, which differed from the traditional IT environment.

With the development of advanced driver assistance systems (ADAS) technologies and the evolution of various automotive applications, such as sensors, radar, high-resolution uncompressed videos, central gateways, infotainment systems, head-up displays, high-resolution screens and 5G connectivity, the bandwidth requirements for IVNs have continued to increase. These requirements surpassed what CAN bus (as well as LIN, FlexRay and other technologies) could provide. Consequently, in 2020, IEEE introduced the 802.3ch standard, which supports data rates of 2.5 Gbps, 5 Gbps and 10 Gbps to meet these growing demands.

Looking ahead, the competitive landscape among various protocols is expected to gradually converge. Ethernet, with its clear advantages in terms of ecosystem, standardization, bandwidth and scalability, is poised to replace MOST, FlexRay and some CAN to become the essential IVN protocol for advanced vehicles. Low-cost LIN will continue to be present in areas where speed and security demands are less critical. Meanwhile, CAN/CAN-FD will remain the primary communication protocol among ECUs for the body, powertrain, chassis and diagnostics.

As automotive E/E architecture shifts from domain-based architecture to centralized zonal architecture, the industry is also witnessing some changes, including the potential need for PCIe.

Figure 1: A timeline of the evolution of in-vehicle protocols.

The future architecture of IVN

The evolution of these IVN standards is driven by the constantly changing demands and technology advancements in the automotive industry. Their emergence represents the evolution of automotive electronic systems, from basic communication to the realization of rich multimedia, ADAS and high-performance capabilities.

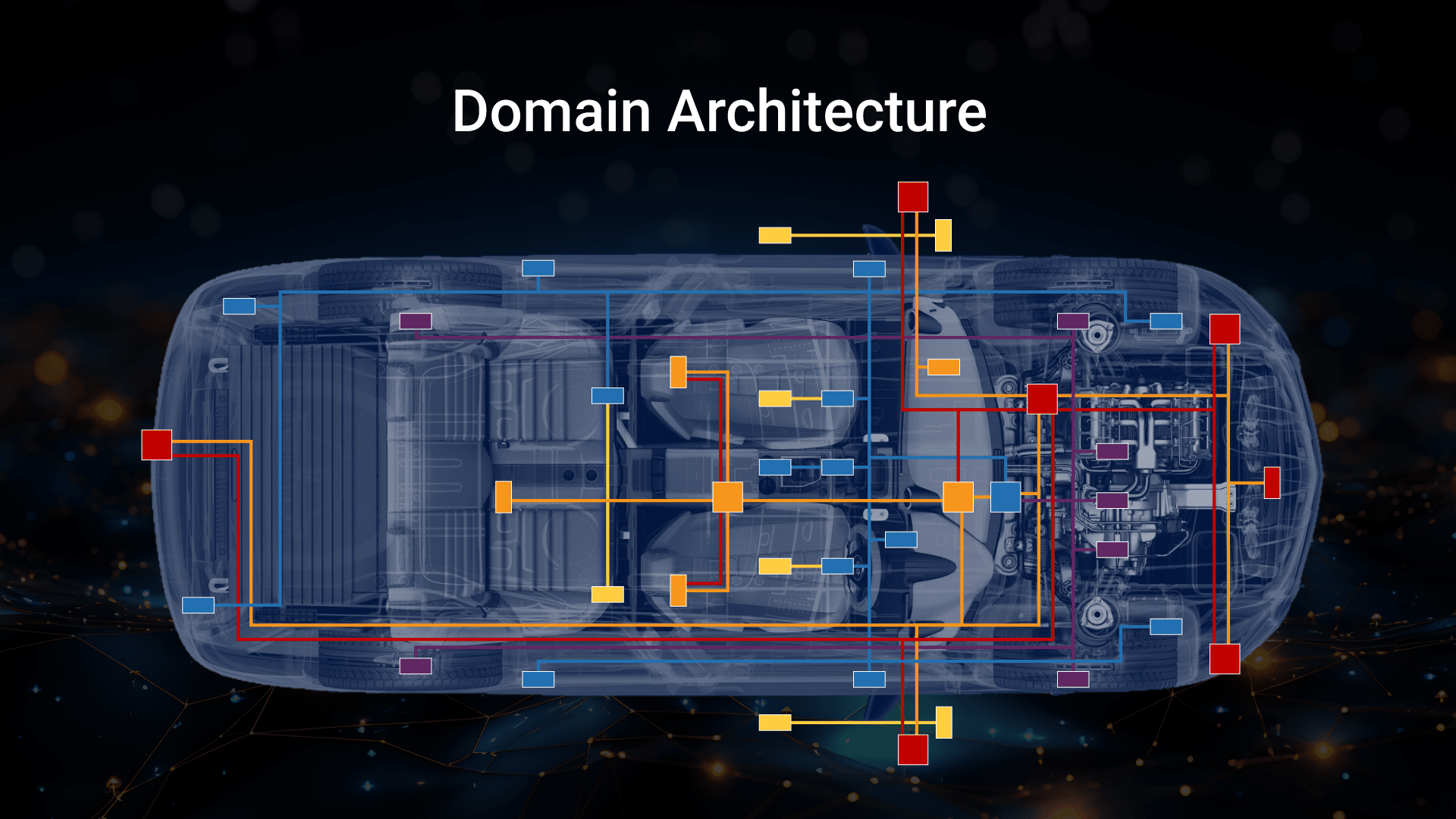

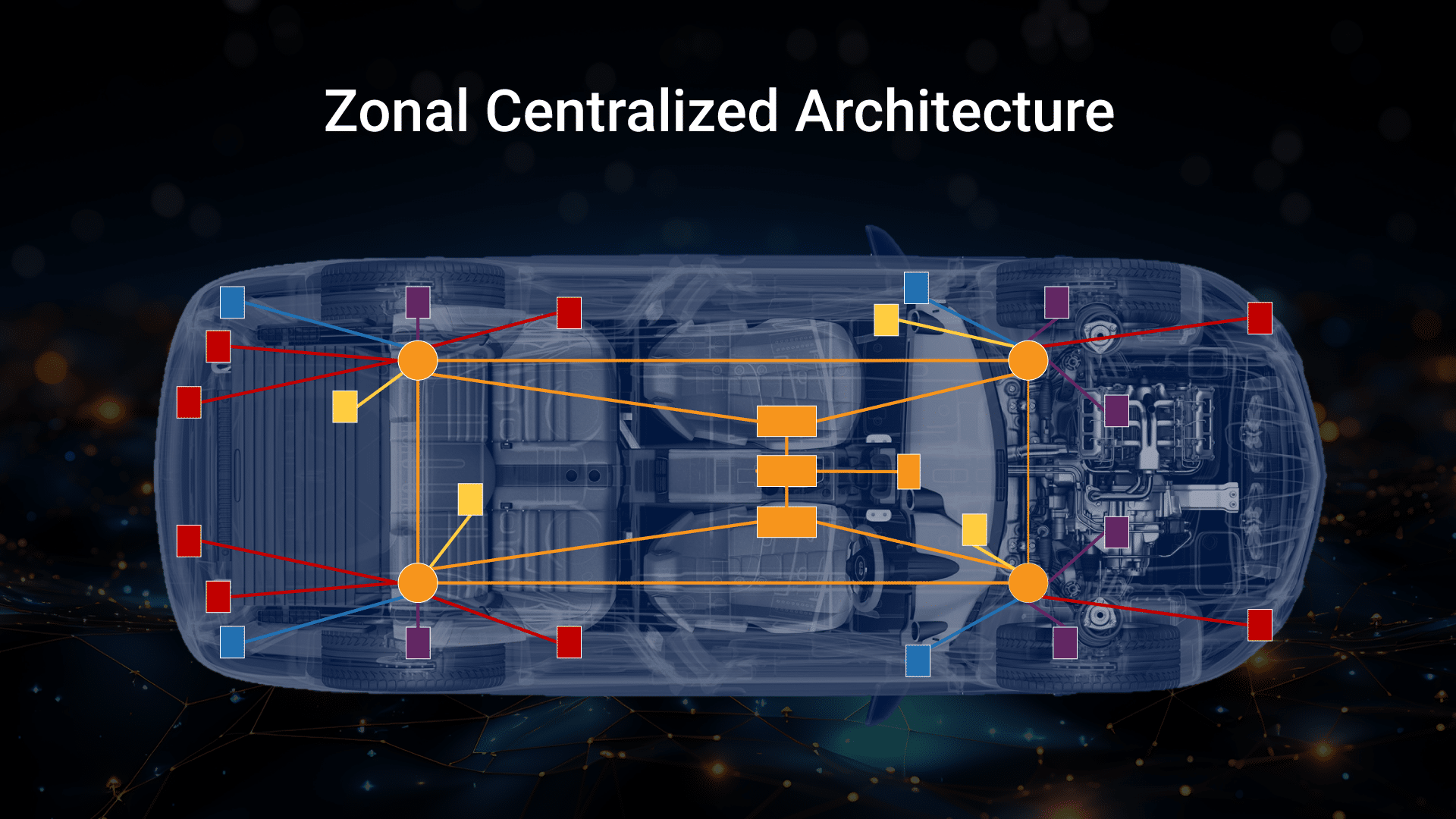

Ethernet not only meets the demands of high data rates, but also enables the possibility of a centralized architecture. In the past, automotive wiring harness could weigh up to 30 kg and is extremely complex. However, a centralized architecture design can significantly reduce the weight, lower the resources required for validation and production and free up more space. Figure 2 illustrates the scenario of adopting various IVN standards in domain architecture and centralized zonal architecture. It can be observed that, with the number of edge ECUs only increasing, transitioning towards a centralized zonal architecture can greatly simplify the wire harness design. Data is pre-processed at the edge through the zonal controller and the computed data is transmitted back to the centralized computing unit via high-speed Ethernet, avoiding the need for extensive and intricate wiring.

Figure 2: A comparison of domain architecture IVN and zonal architecture IVN.

Where is the high-transfer-rate, low-latency PCIe?

In fact, PCIe technology is already being used in automotive systems, including PCIe Wi-Fi chips, GPUs, SSDs, chip-to-chip interconnection and more. PCIe is a highly successful technology widely adopted in server, industrial and consumer electronic applications. It has a future-oriented development roadmap, with the standard bandwidth doubling every few years. PCIe 5.0, with a 32 GT/s data transfer rate per lane, offers excellent scalability with multi-lane configurations and latency in the range of tens of nanoseconds (ns), surpassing the latency of Ethernet, which is measured in microseconds (µs).

Another valuable advantage of PCIe is its extensive ecosystem. Over the past 20 years, PCIe has established a comprehensive and mature ecosystem, with a multitude of PCIe devices, chips and experts available in the market. Phison is a member of the PCIe Automotive Working Group, established by PCIe-SIG in 2021, which is actively working to promote the ecosystem and establish standards specifically for the automotive industry.

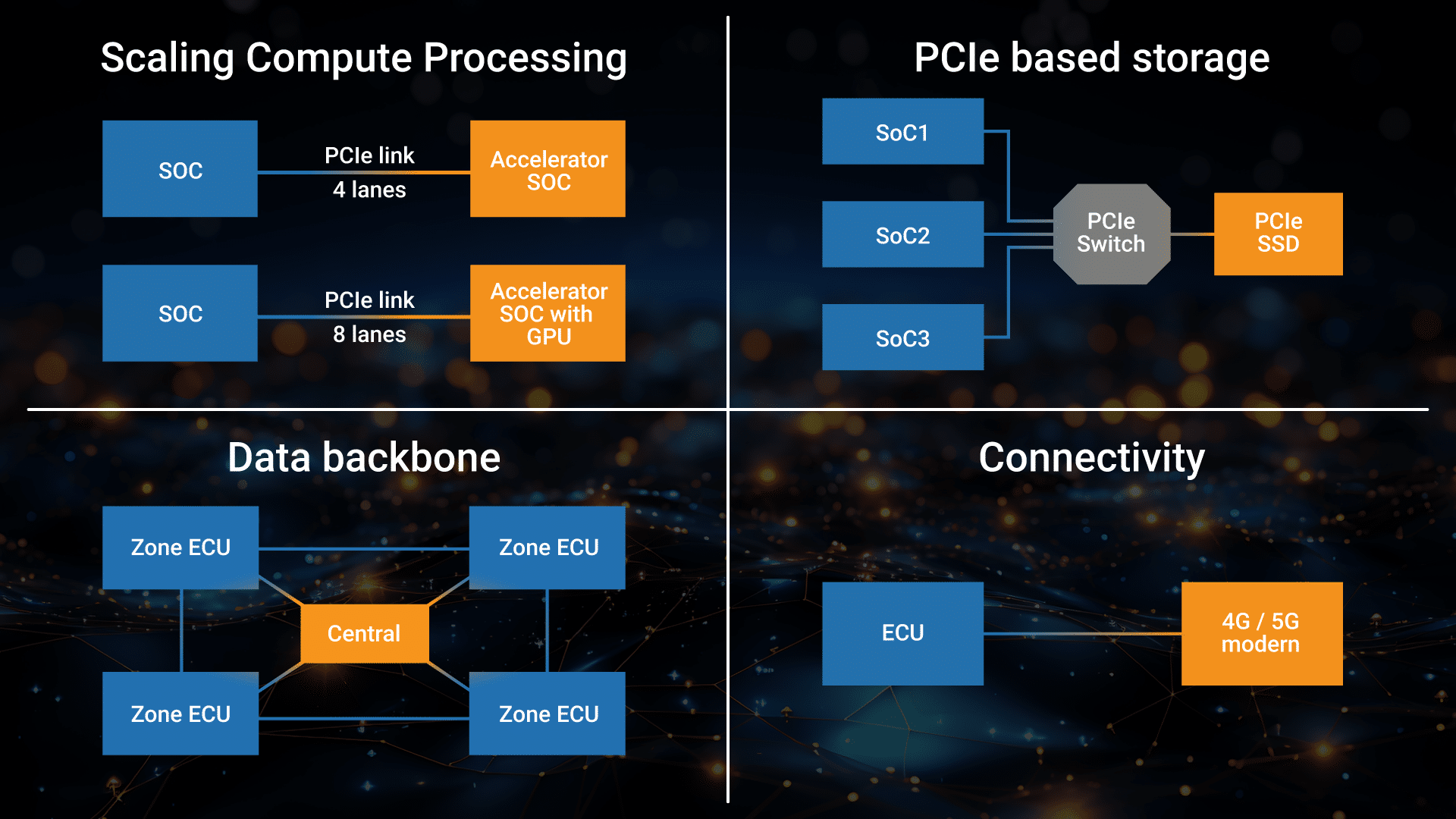

Currently, there are several possible use cases for PCIe in the vehicle:

Figure 3: Potential use cases for PCIe in automobiles.

Scaling compute processing

This is the most common PCIe use case in vehicles, primarily used in advanced driver assistance domain controllers, cockpit domain controllers and interchip communication within the central computing system, including interconnection between systems-on-a-chip (SoCs), GPUs and accelerators.

Data backbone

Currently, Ethernet remains the primary solution in advanced automotive backbones, especially since the introduction of the IEEE 802.3ch standard in 2020, which allows for up to 10 Gbps data rate and the use of shielded twisted pair (STP) cables up to 15 meters in length. This significantly reduces weight and improves data transmission speed. However, the traditional approach involves converting PCIe to Ethernet using a network interface card (NIC) for long-distance ECU interconnection, and then converting back to PCIe at the destination ECU. This approach loses certain advantages of the PCIe protocol, including ultra-low latency, reliability guarantees and support for direct memory access (DMA). Although PCIe still faces technical challenges in long-distance signal transmission in vehicles, it is gradually gaining more attention as advanced system requirements evolve.

PCIe-based storage

As mentioned in our previous article, the abundance of in-vehicle multimedia, ADAS, event data recorders (EDRs), high-definition maps and other applications require faster and larger storage devices. With the consolidation of architectures, there is a growing need for centralized storage, pointing towards advanced PCIe SSDs. There are two potential applications for PCIe SSDs in the system. The first application is relatively straightforward, where one SoC corresponds to one PCIe SSD, commonly seen in the intelligent cockpit system. The second application involves PCIe SSDs in a centralized zonal architecture, where multiple SoCs correspond to one PCIe SSD in a many-to-one design.

Connectivity in the telematic control unit (TCU)

One potential use case is the connection between the TCU and the central gateway or infotainment system. However, due to different architectural designs, the connection between the 4G/5G module or Wi-Fi chip may not necessarily be through long-distance cable connections. It could also be the interconnection between chips on the same board. From an application perspective, it can be considered a hybrid between the first and third use cases mentioned.

So yes! PCIe has been adopted by the automotive industry and experts from around the world are gathered in the Automotive Workgroup of PCI-SIG to discuss challenges like reliability, security, functional safety, thermal, noise, EMI, cable length and more. One of the PCIe technology issues is the signal insertion loss and return loss caused by the complex and challenging in-vehicle environment. PCIe signal conditioning ICs play a crucial role in addressing these signal issues.

PCIe Redriver/Retimer ensure high-quality signals

With the continuous improvement of PCIe transfer rates, signal integrity issues have become more severe, especially with the adoption of PCIe Gen 5 (32 GT/s) by leading automotive chip makers. Even on ultra-low loss printed circuit boards (PCBs), high-speed signals pose significant challenges. Furthermore, complex system designs often require signals to pass through connectors, cables, slots and add-in cards (AICs). However, by incorporating ICs such as Redriver/Retimer between CPU chips and end devices, signal integrity issues associated with high-speed transmission can be effectively resolved.

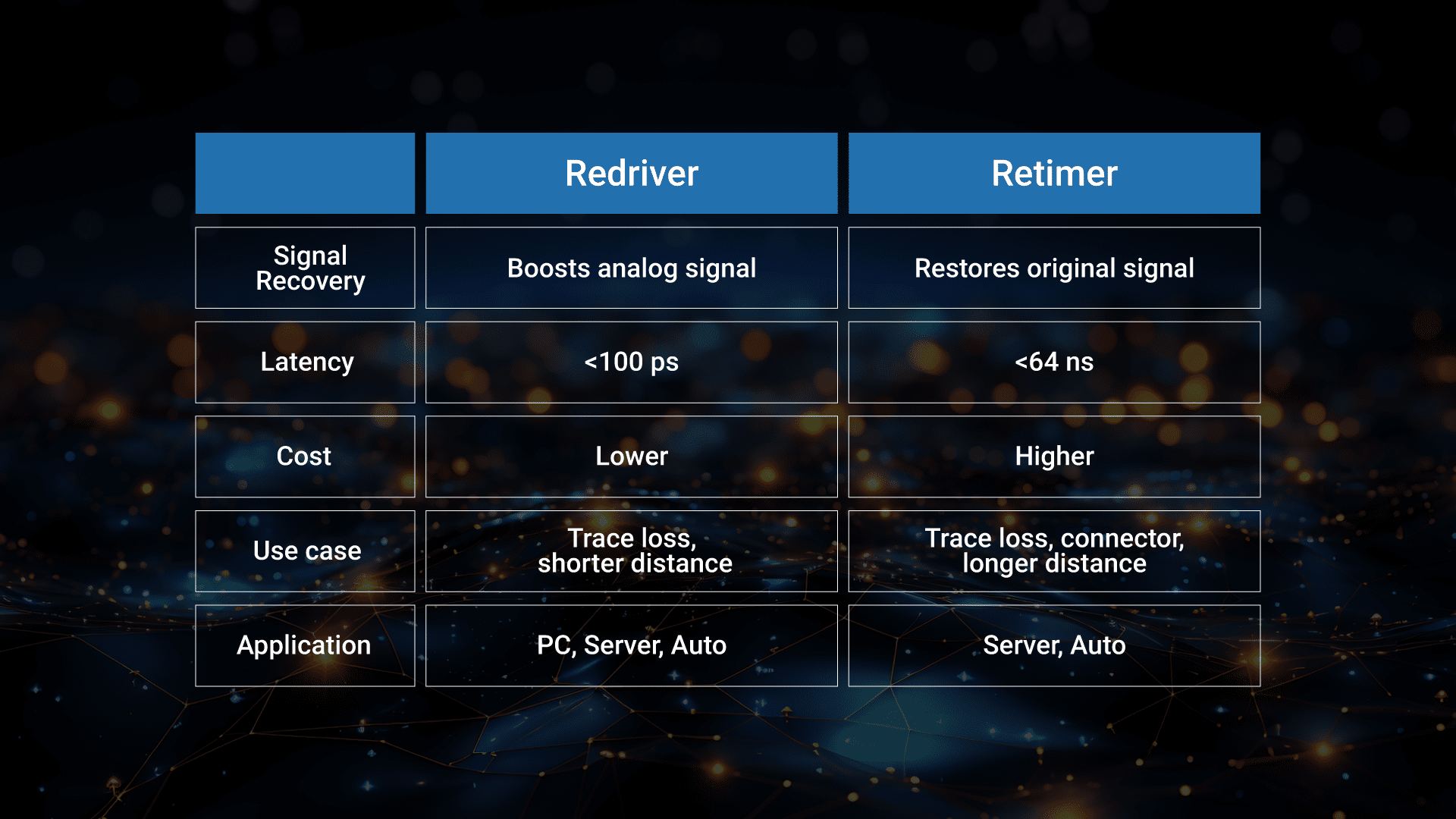

PCIe Redriver and PCIe Retimer are both ICs used for handling PCIe signals, but they have some differences in terms of functionality and application:

Redriver ICs are primarily used for signal enhancement, compensating for signal attenuation. They are commonly used for shorter-distance connections, such as within motherboards. On the other hand, Retimer ICs not only enhance signals, but also recover the data, provide clocking and retransmit a fresh copy of the data. They can recover and compensate for sequence distortions during long-distance transmissions, ensuring high data rate transmission quality. Therefore, Retimer ICs are primarily used in long-distance connections and applications that require higher signal integrity, such as data centers and network devices.

In summary, both PCIe Redriver and PCIe Retimer have signal conditioning capability, but PCIe Retimer has more comprehensive functionality and wider adaptability. It is more suitable for high-quality and long-distance PCIe connection applications, although it may come at a higher cost.

Figure 4: A comparison of Redriver and Retimer ICs.

Phison: Looking further, preparing earlier

The evolution of IVN and E/E architecture are two key elements essential to support the modern driving experience. In the past, IVN mainly relied on protocols such as CAN, LIN, MOST and FlexRay. However, advanced designs with extensive data transmission needs have shifted towards Ethernet and there is even exploration of utilizing PCIe. Although the current use of PCIe is relatively limited, it has many advantages and plays an important role in chip-to-chip interconnection and data storage, making it the subject of extensive industry attention. However, signal loss issues often occur during high-speed transmission, requiring the use of PCIe Redriver/Retimer ICs to solve them.

Phison’s Redriver IC PS7101 is the world’s first PCIe 5.0 Redriver IC certified by PCI-SIG, and the solution lineup of PS7101, 8-channel PS7102 and 16-lane PS7103 has accounted for over 60% market share on motherboards. Phison’s PCIe 5.0 Retimer PS7201 is currently in the sampling phase and is expected to enter mass production in 2024. Although the relevant technology and market are still in the early stages in the automotive industry, Phison has already cooperated with automotive partners to explore PCIe signal solutions for IVNs. Furthermore, Phison has laid out plans for automotive-grade PCIe Redriver/Retimer solutions to cope with the future development of automotive PCIe technology and to be prepared for upcoming challenges and opportunities.