As technologies evolve, organizations are finding more innovative uses for AI, machine learning, augmented reality (AR), virtual reality (VR) and the Internet of Things. These technologies are enabling businesses to quickly and efficiently analyze massive volumes of data—sometimes in real time—and paving the way for exciting new capabilities that have the power to transform virtually any industry.

One of the innovative capabilities that has emerged over the past few years is digital twins. This article will take a closer look at what digital twins are, how they are being used and how they are helping redefine data storage needs for the near future.

What is a digital twin?

A digital twin is a digital replica of a physical person, process, environment or object. It is developed with real-time data gather from multiple sources and an added layer of visualizations and insights from that data. It’s much more than a standard simulation or 3D visualization of a product or process. Digital twins often include AI-derived insights, what-if outcomes and complex visualizations.

An article from industry analysts McKinsey demonstrates the potential scope:

“… a digital twin could provide a 360-degree view of customers, including all the details that a company’s business units and systems collect about them—for example, online and in-store purchasing behavior, demographic information, payment methods, and interactions with customer service. It would also generate insights derived from the data, such as the average length of a customer service call. AI use cases leveraging the twin could include customer churn propensity models or a basket of the next products a customer would be likely to buy.”

Digital twins rely on several advanced technologies to work correctly: big data, or enormous amounts of information from a wide range of sources; devices connected to the Internet of Things, such as sensors that gather data in an environment; data analytics to parse that data and extract valuable insights from it; AI and machine learning to draw correlations and make predictions or recommendations for optimization; and AR/VR, which often serves as an interface between the user and the digital twin (for example, a technician wears smart glasses that project a digital overlay onto a physical machine to get guidance on how to repair it).

Digital twins can benefit most industries

Many industries are using digital twins to improve processes, develop new products, streamline operations, maintain equipment and more. Some examples include:

-

-

- Automotive – Feedback from vehicles in testing is sent to a digital twin to assess performance, evaluate component effectiveness and suggest needed improvements. Digital twins are also used in the design and manufacture of vehicles.

-

-

-

- Manufacturing – A digital twin of a manufacturer’s assembly line can help identify production bottlenecks and inefficient processes. A digital twin of a complex products with many components, such as an engine, can help predict potential vulnerabilities and aid in predictive maintenance.

-

-

-

- Smart cities – Some digital twins are as large and complex as an entire city. These models can help city leaders make smarter decisions about infrastructure, city services and public safety.

-

-

-

- Sports and entertainment – A digital twin of a stadium can help organizations optimize traffic flow, retail locations, safety parameters and more.

-

-

-

- Aerospace – Making digital twins of a spacecraft allows scientists to test a wide range of situations without putting very costly physical equipment in jeopardy.

-

-

-

- Engineering – Digital twins of prospective projects, from bridges to construction cranes to intricate medical devices, can help engineers fine-tune designs and create safer, more usable products before even making a prototype.

-

-

-

- Medical research – Researchers could do a lot with a digital twin of the human brain or immune system, from testing the reaction of new drugs to seeing how substances affect cognitive thinking.

-

-

-

- Architecture/construction – Digital twins of buildings and their infrastructure can help architects and construction executives identify areas that need improvement or impending safety issues.

-

-

-

- Energy – The energy sector can use digital twins to monitor and analyze performance of wind farms, electricity grids and municipal water systems to see where maintenance is needed and keep small problems from getting bigger.

-

-

-

- Retail – Digital twins of stores can help retailers optimize store design and layout. It can give great insights into how to place products and gain shoppers’ attention.

-

-

-

- Enterprise data centers – A recent article reported that some enterprises are beginning to use digital twins to optimize their data centers. The twin enables organizations to see how various data center designs and equipment placement options will affect performance. It can even show IT how different workloads would be impacted over time while including variables such as energy usage and cooling needs.

-

The popularity of digital twins is rising. McKinsey found that 70 percent of today’s tech enterprise executives are either exploring the use of digital twins or have already invested in them. IDC predicted that the number of physical assets with digital twins will increase from 5% in 2021 to 60% by 2027.

Benefits of digital twins

Digital twins can optimize processes and operations and help speed up time to market. With AI and machine learning capabilities, they can even help decrease errors in processes and production and help an organization improve equipment effectiveness and efficiency.

Organizations can also save money using digital twins in development because the twins enable very fast iterations and testing—much more speedy than having to create and test every prototype physically. Digital twins also help teams identify design or other quality issues much sooner in the process, again because they don’t have to create the physical piece to find the flaws.

Improved performance is also another benefit of digital twins, especially when it comes to a digital twin of an entire facility or the complete production line of a product, for instance. Insights from those digital twins enable organizations to deal with issues faster to reduce downtime and optimize systems to operate at peak efficiency.

Digital twins can also alert teams to potential breakdowns of equipment or machinery so they can perform maintenance tasks or repair a small problem before it becomes more serious.

Data storage matters when it comes to digital twins

Digital twins are very complex and require (and generate) a lot of data. In fact, there is no digital twin without data. They need high volumes of information fed to them in real time and latency of even a few milliseconds can be a problem in some industries. They depend on multiple advanced technologies to create the insights and optimizations they’re known for. Data storage is critical to keeping digital twins effective and operational.

Data storage for digital twins must be high performance with low latency and be able to keep up with the split-second demands of the twin. It must have significant capacity and be extremely scalable, accessible and reliable.

Enterprise-grade, high-capacity SSDs are a smart choice for storing the data of digital twins. They’re optimized for endurance and stability at the highest levels of performance and speed where it’s needed most. SSDs are able to meet the stringent performance and reliability demands of data-intensive workloads and provide the efficiency and security that most organizations need to comply with data regulations.

When planning data storage to support a digital twin (or other technology such as AI, machine learning or data analytics), one manufacturing expert urged readers to look for the following criteria in their SSD storage solution:

- Capacity and speed for ultra-quick, real-time data processing and access

- Reliability and endurance for dependable long-time use in a range of environments and conditions Customization to meet unique needs for specific applications

- Condition monitoring that alerts you to potential issues or errors

- Compliance with industry standards for quality control as well as data privacy and security

Phison offers performance for the most intensive workloads

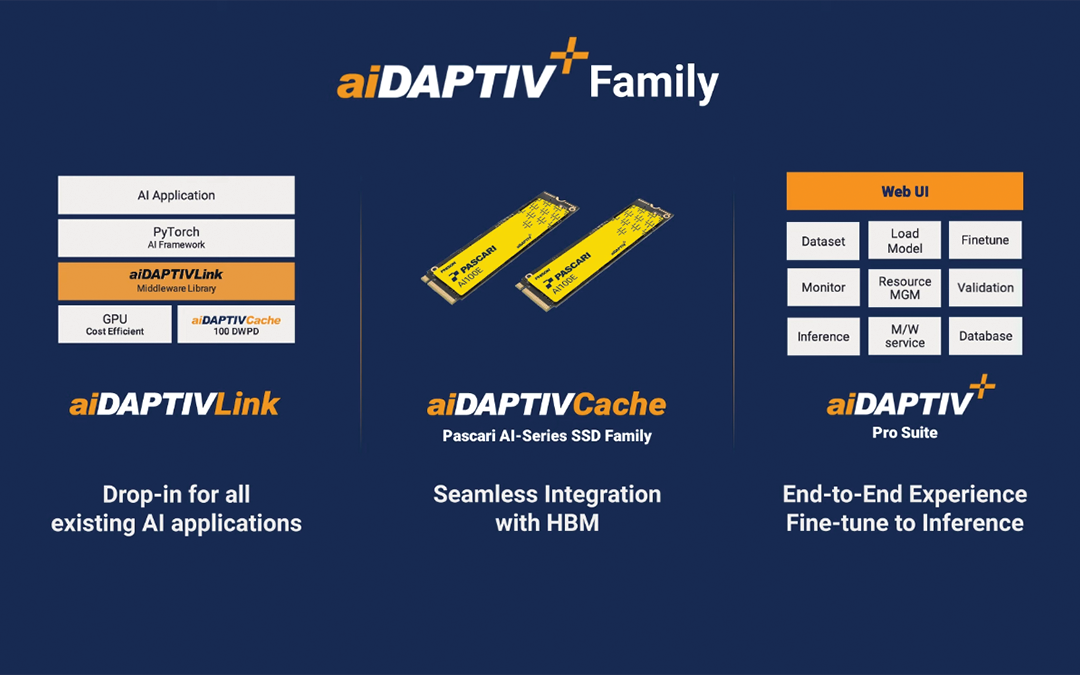

Phison offers a range of enterprise SSDs that meet the criteria above and that are designed for heavy workloads such as those found in AI, machine learning, data analytics—and digital twin—projects. As an industry leader in NAND flash and other data storage solutions, Phison designs its own NAND controller ICs, private-label SSDs and a wide range of NAND storage solutions for organizations that require high-performance, low-latency data storage that consumes little energy. The company’s IMAGIN+ customization service, now expanded with aiDAPTIV+ to include AI services, enables organizations to get the NAND flash data storage they need regardless of technical requirements.

Phison continually invests heavily in R&D to remain on the cutting-edge of technological advancement so enterprises can rely on Phison to meet their complex data storage needs both today and tomorrow.

Additional AI Content from Phison