Heutige Unternehmensrechenzentren stehen ständig vor der Herausforderung, Leistung, Geschwindigkeit und Kühleffizienz mit dem begrenzten Platz im Server-Rack in Einklang zu bringen. Beim Speicher ist es noch wichtiger, die richtige Balance zu finden. Eines der größten Hindernisse für dieses Gleichgewicht sind jedoch die Formfaktoren. Viele traditionelle Formfaktoren wurden für Festplattenlaufwerke (HDDs) und nicht für Solid-State-Laufwerke (SSDs) entwickelt. Daher mangelt es ihnen an der Kühleffizienz und Speicherkapazität, die für große Rechenzentren erforderlich sind.

Obwohl SSDs schneller, langlebiger, leistungsfähiger und energieeffizienter als HDDs sind, stand die Branche vor einigen Herausforderungen, als Unternehmen anfangs auf SSDs umstiegen. Die ersten SSDs gab es in den Größen 2,5 Zoll und 3,5 Zoll. Formfaktoren passend zur Größe von HDD-Gehäusen. Das ermöglichte Unternehmen den einfachen Umstieg auf SSDs, ohne größere Änderungen an ihrer Infrastruktur vornehmen zu müssen. Das mechanische Design der 2,5-Zoll- und 3,5-Zoll-Gehäuse, die ursprünglich für HDDs konzipiert waren, blockierte jedoch den Luftstrom der SSD und schränkte ihre Skalierbarkeit ein.

SSDs in allen Formen, Größen und Funktionen

SSDs gibt es heute in den unterschiedlichsten Formfaktoren, von den ursprünglichen 2,5-Zoll- und mSATA-Modellen bis hin zu U.2 und M.2. Diese Vielfalt ermöglicht es Benutzern, die passenden SSDs für ihre Bedürfnisse auszuwählen, beispielsweise hinsichtlich Größenbeschränkungen, Skalierbarkeit und Leistungsanforderungen.

Alle diese SSD-Formfaktoren eigneten sich hervorragend für den allgemeinen SSD-Einsatz, waren jedoch nicht für den Einsatz in Unternehmensrechenzentren optimiert. Unternehmen benötigten SSDs mit höherer Kapazität, Skalierbarkeit, Leistung, Wärmemanagement und Energieeffizienz, um ihre anspruchsvollsten und intensivsten Workloads bewältigen zu können.

EDSFF reagiert auf die Anforderungen von Unternehmensrechenzentren

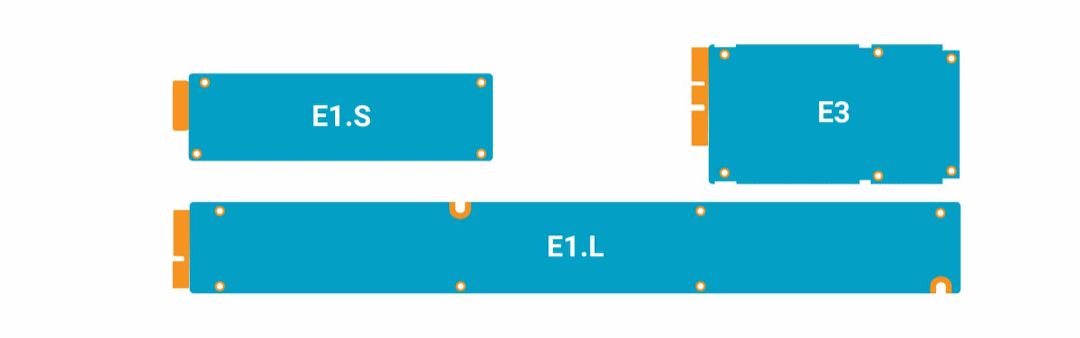

Vor etwa fünf Jahren hat eine Expertengruppe der Verband der Speichernetzwerkindustrie hat den Enterprise and Datacenter Standard Form Factor (EDSFF) entwickelt, um die Einschränkungen aktueller SSD-Formfaktoren zu überwinden und Unternehmen bessere Optionen zu bieten. Alle EDSFF-Formfaktoren nutzen das NVMe-Protokoll und PCIe-Schnittstellen sowie den gleichen Randstecker, die gleiche Pinbelegung und die gleichen Funktionen. E1 und E3 waren die ersten von EDSFF angekündigten Formfaktoren (Abbildung 1).

Abbildung 1. EDSFF E1- und E3-Formfaktoren, eingeführt Ende 2020

E1.S

Dieser Formfaktor ist die beliebteste Variante der EDSFF-Familie und ersetzt mit seinem mechanischen Design die M.2-Laufwerke im Rechenzentrum. Er bietet höhere Dichte und Leistung bei gleichzeitig geringer Größe. Er ist zudem Hot-Plug-fähig, sodass die IT-Abteilung das Laufwerk austauschen kann, ohne das System auszuschalten. Der E1.S hat die Form eines Kaugummistreifens und passt in eine 1HE-Einheit. Ein 1HE-Speicherserver kann bis zu 32 E1.S-Speicherlaufwerke unterstützen. Dadurch kann das Rechenzentrum die Speicherkapazität skalieren und das Daten- und Anwendungswachstum unterstützen.

E1.L

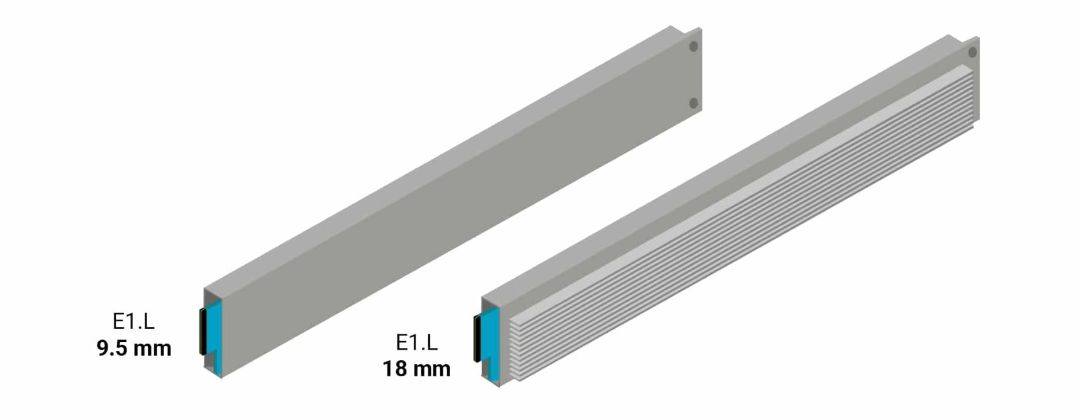

E1.L ist Hot-Plug-fähig, hat die Form eines langen Lineals und ist für 1U-Server optimiert. Der maximierte Platz auf der Platine kann mehr NAND-Flash-Pakete unterstützen und die Kühleffizienz verbessern. Normalerweise verwendeten Unternehmen den U.2-Formfaktor für Laufwerke mit großer Kapazität, aber manchmal wurden die U.2-Laufwerke mit großer Kapazität mit zwei umgeklappten Leiterplatten gebaut. Die Komponenten im Inneren ähnelten der Mitte eines Sandwichs, und die von diesen Komponenten ausgehende Wärme ließ sich nur schwer abkühlt. E1.L löst das thermische Problem, indem die gesamte Fläche auf die Oberfläche verteilt wird, zusammen mit zwei Dickenoptionen für das Metallgehäuse (Abbildung 5). Es benötigt beim 55% weniger Luftstrom als der U.2-Formfaktor und die Stromkosten werden ebenfalls erheblich reduziert. E1.L ist der dichteste Speicherformfaktor. Ein einzelner 1U-Speicherserver voller E1.L-Laufwerke kann eine Kapazität von 1 PB erreichen. Unternehmensrechenzentren können E1.L verwenden, um die Dichte zu erhöhen und gleichzeitig die Gesamtbetriebskosten (TCO) zu senken.

Abbildung 2. E1.L-Wärmeoptionen

E3

Der größte Unterschied zwischen E3-Laufwerken und den anderen Formfaktoren der EDSFF-Familie liegt in der Form. E3 ähnelt optisch dem traditionellen 2,5-Zoll-Formfaktor, ermöglicht aber bis zu x16 PCIe-Lanes und 70 W Leistung. Es wurde entwickelt, um den U.2-Formfaktor zu aktualisieren und zu ersetzen.

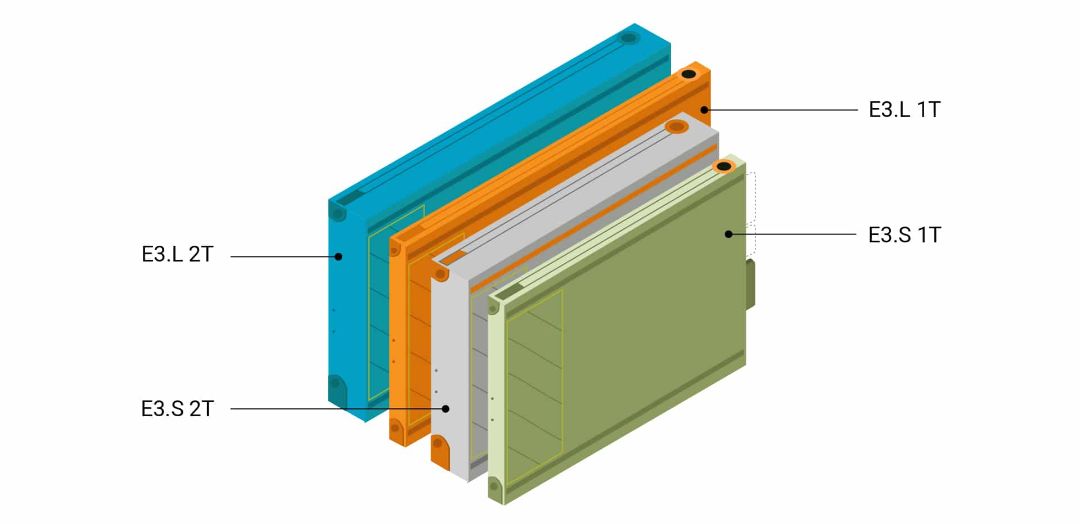

E3 ist Hot-Plug-fähig und für 1U- und 2U-Server optimiert. Es gibt vier verschiedene Varianten: E3.L und E3.S sowie in einfacher (1T) oder doppelter (2T) Breite, wobei T für die Dicke steht (Abbildung 3). Aufgrund der verbesserten Wärmeableitung wird 2T typischerweise für Hochleistungsgeräte verwendet, die mehr Wärme erzeugen, wie z. B. Rechenspeicher und Speicher mit hoher Kapazität.

Abbildung 3. Variationen von E3

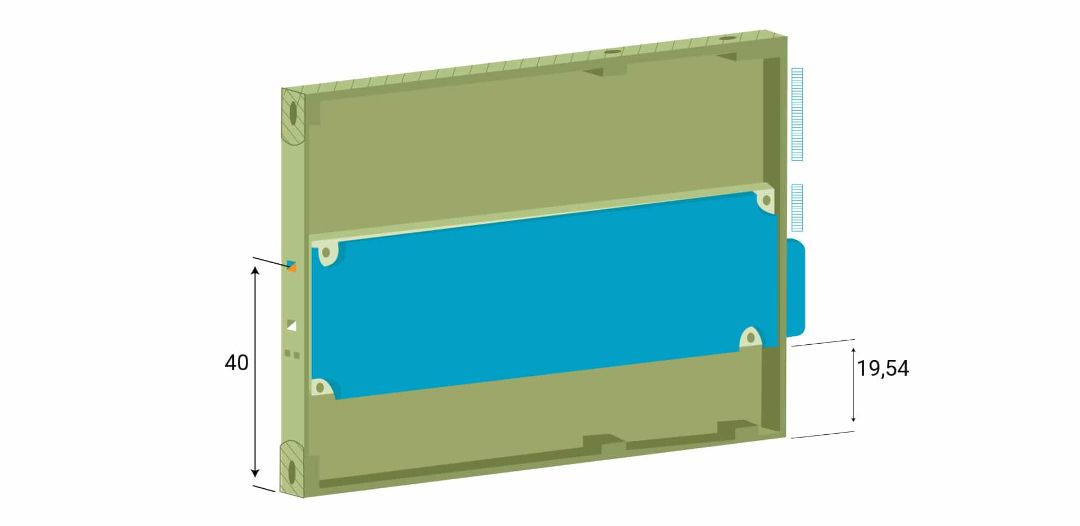

Auch von innen ist E3 flexibel. Eine kleine E1.S-PCBA passt in ein E3-Gehäuse, sodass Speicher mit geringer Kapazität und E3-Formfaktor die E1.S-PCBA zur Kostensenkung nutzen können (Abbildung 4). Darüber hinaus unterstützt E3 neben SSDs eine Vielzahl von Gerätetypen, beispielsweise persistenten Speicher.

Abbildung 4. E1.S im E3-Gehäuse

E2

Der E2-Formfaktor wurde im Mai 2025 beim OCP Storage Tech Talk vorgestellt und schließt die wachsende Lücke zwischen Festplatten mit hoher Kapazität und Hochleistungs-SSDs (Abbildung 5). Er ist für die neue „warme“ Datenebene konzipiert, die aus Informationen besteht, auf die für langsame HDDs zu häufig zugegriffen wird, die aber die Kosten für SSDs der Spitzenklasse nicht rechtfertigen.

Mit Unterstützung von bis zu 1 Petabyte pro Laufwerk in einem Standard-2U-Server ist E2 auf Skalierbarkeit ausgelegt. Als Teil der „Ruler“-Bezeichnung von EDSFF sind E2-Laufwerke 7,9 x 3 x 0,4 Zoll groß. Ein einzelnes Gehäuse kann bis zu 40 Laufwerke aufnehmen und so eine beeindruckende Kapazität von 40 PB erreichen – bei gleichzeitiger Reduzierung von Platzbedarf und Stromverbrauch pro Terabyte. Das Hot-Plug-fähige, von vorne zugängliche Design ermöglicht eine schnelle und problemlose Wartung und minimiert Ausfallzeiten in anspruchsvollen Umgebungen.

E2 nutzt den branchenüblichen EDSFF-Anschluss und gewährleistet so umfassende Kompatibilität und zukunftssichere Skalierbarkeit. Trotz des höheren Stromverbrauchs bietet es eine deutlich bessere Energieeffizienz pro TB als HDDs. Dies macht es zur intelligenten Wahl für Rechenzentren, die Wert auf die Reduzierung von Gesamtbetriebskosten und Energieverbrauch legen.

Phison SSDs bieten überlegene Leistung und Kapazität

Mit seinem Engagement für die kontinuierliche Weiterentwicklung der Datenspeichertechnologie bietet Phison jetzt das Enterprise Gen5 NVMe-Laufwerk mit der höchsten Kapazität im leistungsoptimierten E3.L-Formfaktor. Das Phison Pascari D205V SSD verfügt über eine enorme Kapazität von 122 TB und zeigt, wie Formfaktoren der nächsten Generation wie E3.L die Möglichkeiten der Speicherdichte, thermischen Effizienz und Skalierbarkeit in der Unternehmensinfrastruktur neu definieren.

Abbildung 5. Phisons Pascari D205V SSD ist in verschiedenen Formfaktoren erhältlich

Der E3.L-Formfaktor wurde für Umgebungen mit hoher Dichte und hoher Leistung entwickelt und bietet im Vergleich zu älteren U.2- und U.3-Designs eine verbesserte Luftzirkulation und ein besseres Wärmemanagement. Dies macht ihn ideal für KI-Trainingscluster, Hyperscale-Umgebungen und dichte Edge-Bereitstellungen, bei denen Kühlung und physischer Platz kritische Einschränkungen darstellen.

Die Pascari D205V 122 TB SSD bietet unübertroffene Kapazität pro Steckplatz und ermöglicht es Kunden, datenintensive Workloads wie KI-Training und maschinelles Lernen, Echtzeitanalysen und Cloud-Speicher effizienter zu bewältigen. Dies reduziert nicht nur den Platzbedarf im Rack, sondern senkt auch die Betriebs- und Energiekosten und vereinfacht die Infrastrukturplanung für Unternehmen, die am Edge oder im Rechenzentrum skalieren.

Phison erweitert weiterhin die Grenzen dessen, was in Serverarchitekturen der nächsten Generation heute möglich ist, damit Sie die Anforderungen von morgen erfüllen können. Unternehmens-Workloads mit skalierbarer Innovation.